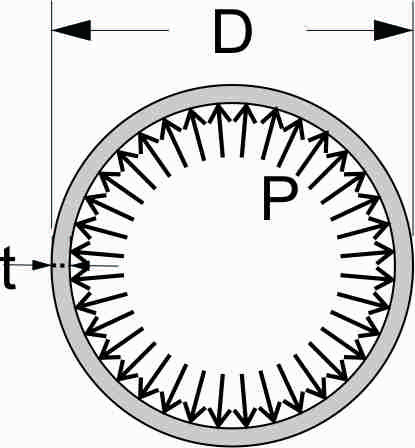

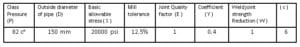

W= Weld joint strength reduction factor in accordance with ASME B 31.3 para. P = internal design gage pressure in psi (g) at design temperature of 82 0C. A: Allowance for threading, grooving, corrosion. If you want more ASTM materials to be included, please mention in comments section below. A pipe thickness calculator is a tool that calculates the pipe thickness when all required inputs are supplied. ; Little P.Eng. 3). consideration of factors listed in para. The value of W can be found from Table 302.3.5 of ASME B 31.3 (Refer to Fig. Value islinearly interpolatedfor intermediate temperatures. Also, why did you use the mill tolerance to divide the thickness instead of addition of the mill tolerance to the thickness? Hence, The designers need to find out the required piping thickness as per section 304.1.2 of ASME B31.3 to resist the internal line pressure. Since calculated thickness valuable Please refer the Table A-1 of ASME B31.3 to get the allowable stress value. (adsbygoogle=window.adsbygoogle||[]).push().  Meena Rezkallah. 7).

Meena Rezkallah. 7).  What is the maximum requirement of extra thickness for each pipe size?Ex: If the extra thickness is below 1mm, could we select another next greater value schedule?

What is the maximum requirement of extra thickness for each pipe size?Ex: If the extra thickness is below 1mm, could we select another next greater value schedule?  304.1.2(b) of 31.3. class pressure or internal gauge pressure? For our case material A106 Gr. If the above condition ever comes then the calculation of internal design pressure thickness for straight pipe requires special consideration of factors such as the theory of failure,effects of fatigue, and thermal stress. Note this number down on a piece of paper as well.

304.1.2(b) of 31.3. class pressure or internal gauge pressure? For our case material A106 Gr. If the above condition ever comes then the calculation of internal design pressure thickness for straight pipe requires special consideration of factors such as the theory of failure,effects of fatigue, and thermal stress. Note this number down on a piece of paper as well.  In accordance

In accordance  Hence, the pipe wall thickness can directly be calculated easily using the pipe outer diameter. thickness pipe nominal selection od basic actual Process plants deal with fluids those are mostly chemical in nature with varying pressure and temperature .these fluids are transported from one point to another through pipes. Can you provide some industrial applications of ultrasonic waves. is 8.118 is less than 25, ASME B31.3 eq. Follow the below steps to get the required pipe thickness-, Put the above found values in the equation (3a) shown in Fig. table 302.3.5 W = 1.0 for carbon Fluid could be corrosive and toxic in the system. thickness b31 asme transporting The value of E, Longitudinal Weld Joint Quality Factor, or Casting Quality Factor can be found in Table A-1A or Table A-1B of the ASME B31.3. I hope You have got the overview of the pipe wall thickness calculation, You can practice for other cases following the mentioned steps for better understanding. insulation pipe thickness chart correct condensation fiberglass sizing Place your ruler or measuring tape over the mouth of the pipe. It may be 0mm, 3mm, 6mm or project specific requirements. Engineering Services Torrance, California, Engineering Services Buena Park, California, 3705 Fonda Way. Value of W is taken as 1.0 at temperatures of 510C(950F) and below, and 0.5 at 815C (1500F) for all materials. 6) and for our problem case, the value of W is 1. So be with me for the next couple of years! < D/6 =

Hence, the pipe wall thickness can directly be calculated easily using the pipe outer diameter. thickness pipe nominal selection od basic actual Process plants deal with fluids those are mostly chemical in nature with varying pressure and temperature .these fluids are transported from one point to another through pipes. Can you provide some industrial applications of ultrasonic waves. is 8.118 is less than 25, ASME B31.3 eq. Follow the below steps to get the required pipe thickness-, Put the above found values in the equation (3a) shown in Fig. table 302.3.5 W = 1.0 for carbon Fluid could be corrosive and toxic in the system. thickness b31 asme transporting The value of E, Longitudinal Weld Joint Quality Factor, or Casting Quality Factor can be found in Table A-1A or Table A-1B of the ASME B31.3. I hope You have got the overview of the pipe wall thickness calculation, You can practice for other cases following the mentioned steps for better understanding. insulation pipe thickness chart correct condensation fiberglass sizing Place your ruler or measuring tape over the mouth of the pipe. It may be 0mm, 3mm, 6mm or project specific requirements. Engineering Services Torrance, California, Engineering Services Buena Park, California, 3705 Fonda Way. Value of W is taken as 1.0 at temperatures of 510C(950F) and below, and 0.5 at 815C (1500F) for all materials. 6) and for our problem case, the value of W is 1. So be with me for the next couple of years! < D/6 =  This is because the outside diameter of the pipe is constant, it is independent of the wall thickness. https://en.wikipedia.org/wiki/Cylinder_stress, https://www.offshore-mag.com/articles/print/volume-58/issue-3/news/pipeline/determining-wall-thickness-for-deepwater-pipelines.html, https://books.google.com.bo/books/about/Valves_Piping_and_Pipelines_Handbook.html?id=bTLu6OSYmcAC&redir_esc=y, Everyone who receives the link will be able to view this calculation, Copyright PlanetCalc Version:

Corrosion allowance is not fixed for all the cases, it may vary from line to line and from project to project. Valid for t < D/6and for materials shown. what is the relation between the figure 20 years and 7200 cycles? In a summary we know all parameters used in equation. 2, P = [2(T-C)EW/{D-2(T-C)Y}]*S = [2(6.59)*1*1/{168.3 2*(6.59)0.4}*17900where, T-C will be ordering thickness minus mill tolerance (12.5%) minus corrosion allowance (3 mm), So,P = (13.18/163.02)*17900 = 1447 PSIG (This will always be higher than the design pressure), To get the required thickness for manufacturing bend see the below formula-, Thickness required for bend = Required pipe thickness/0.9 = 10.72/0.9 = 11.91 mm. Screen shot of scrolled page as below for reference. Keep doing good Job. For Cross-country pipelines, we use the next thickness of the chart for economic purposes. Measure the diameter from the top inner wall to the bottom inner wall. For checking extra thickness is sufficient to take care of thinning, if the same pipe is used for manufacturing the bend. So from Fig. If the project required plant life more than 20 years then the corrosion allowance will be taken more as per the number of years. The minimum required thickness of a pipe must be calculated to ensure. Refer to Table 304.1.1 of ASME B31.3 for finding the value of Y, It is Valid for t < D/6and materials shown below The value of Y maybe interpolated for intermediate temperatures.

This is because the outside diameter of the pipe is constant, it is independent of the wall thickness. https://en.wikipedia.org/wiki/Cylinder_stress, https://www.offshore-mag.com/articles/print/volume-58/issue-3/news/pipeline/determining-wall-thickness-for-deepwater-pipelines.html, https://books.google.com.bo/books/about/Valves_Piping_and_Pipelines_Handbook.html?id=bTLu6OSYmcAC&redir_esc=y, Everyone who receives the link will be able to view this calculation, Copyright PlanetCalc Version:

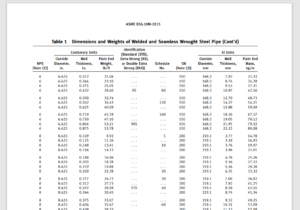

Corrosion allowance is not fixed for all the cases, it may vary from line to line and from project to project. Valid for t < D/6and for materials shown. what is the relation between the figure 20 years and 7200 cycles? In a summary we know all parameters used in equation. 2, P = [2(T-C)EW/{D-2(T-C)Y}]*S = [2(6.59)*1*1/{168.3 2*(6.59)0.4}*17900where, T-C will be ordering thickness minus mill tolerance (12.5%) minus corrosion allowance (3 mm), So,P = (13.18/163.02)*17900 = 1447 PSIG (This will always be higher than the design pressure), To get the required thickness for manufacturing bend see the below formula-, Thickness required for bend = Required pipe thickness/0.9 = 10.72/0.9 = 11.91 mm. Screen shot of scrolled page as below for reference. Keep doing good Job. For Cross-country pipelines, we use the next thickness of the chart for economic purposes. Measure the diameter from the top inner wall to the bottom inner wall. For checking extra thickness is sufficient to take care of thinning, if the same pipe is used for manufacturing the bend. So from Fig. If the project required plant life more than 20 years then the corrosion allowance will be taken more as per the number of years. The minimum required thickness of a pipe must be calculated to ensure. Refer to Table 304.1.1 of ASME B31.3 for finding the value of Y, It is Valid for t < D/6and materials shown below The value of Y maybe interpolated for intermediate temperatures.  Few Important PostsPipe Rack Design and CalculationsHydrotest Procedure for Piping systemOlets Fittings: A Complete Guide. link to What Are Refractory Metals? Measure the diameter of the pipe from the top of the outer wall to the bottom of the outer wall. so corrosion allowance may vary from places to places. ASME B36.10 : Welded and Seamless Wrought Steel Pipe. if(typeof ez_ad_units!='undefined'){ez_ad_units.push([[300,250],'whatispiping_com-banner-2','ezslot_4',851,'0','0'])};if(typeof __ez_fad_position!='undefined'){__ez_fad_position('div-gpt-ad-whatispiping_com-banner-2-0')};report this ad, Pipe Thickness Calculation as per ASME B31.3 | Pipe Thickness Calculator (With PDF). Check the next Ordering thickness available in ASME B36.10M considering the required thickness. If our pipe grade specified as Astm A 135 Electric resistance welded then W value would be 0.85 as shown below. get design pressure with interpolation method as shown below. Step 4. 5). Hence as per Ordering thickness for the seamless pipe is always the next greater value available from Schedule to schedule only2. Hence it will not have the required thickness for the above mentioned service conditions. For example: at 625 F, the stress value will be between 17.3 and 17.9 ksi, i.e; 17.6 ksi, we can get this value by interpolation. The required thickness of straight section of pipe shall be determined by following equation (1a), c = mechanical allowance (thread and grove) +corrosion and erosion allowance, to calculate t = pressure design thickness in above it has given formulae in para 304.1.2, that says for t D/6 the internal pressure design thickness for straight pipes shall not be less than the calculated in accordance with either eq (3a) below or (3b), Where P = Internal design pressure (psig), S =Stress value from material table A-1 B31.3 (psi), E = Weld joint quality factor from Table A-1a (for casting) or A-1b (for tube/pipe), W = Weld joint strength reduction factor from Para 302.3.5.e, Y = Temp dependent co efficient from Table 304.1.1. i.e. As per clause 304.1.2 (a) of ASME B 31.3, the internal pressure design thickness for straight pipes with t

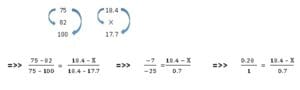

Few Important PostsPipe Rack Design and CalculationsHydrotest Procedure for Piping systemOlets Fittings: A Complete Guide. link to What Are Refractory Metals? Measure the diameter of the pipe from the top of the outer wall to the bottom of the outer wall. so corrosion allowance may vary from places to places. ASME B36.10 : Welded and Seamless Wrought Steel Pipe. if(typeof ez_ad_units!='undefined'){ez_ad_units.push([[300,250],'whatispiping_com-banner-2','ezslot_4',851,'0','0'])};if(typeof __ez_fad_position!='undefined'){__ez_fad_position('div-gpt-ad-whatispiping_com-banner-2-0')};report this ad, Pipe Thickness Calculation as per ASME B31.3 | Pipe Thickness Calculator (With PDF). Check the next Ordering thickness available in ASME B36.10M considering the required thickness. If our pipe grade specified as Astm A 135 Electric resistance welded then W value would be 0.85 as shown below. get design pressure with interpolation method as shown below. Step 4. 5). Hence as per Ordering thickness for the seamless pipe is always the next greater value available from Schedule to schedule only2. Hence it will not have the required thickness for the above mentioned service conditions. For example: at 625 F, the stress value will be between 17.3 and 17.9 ksi, i.e; 17.6 ksi, we can get this value by interpolation. The required thickness of straight section of pipe shall be determined by following equation (1a), c = mechanical allowance (thread and grove) +corrosion and erosion allowance, to calculate t = pressure design thickness in above it has given formulae in para 304.1.2, that says for t D/6 the internal pressure design thickness for straight pipes shall not be less than the calculated in accordance with either eq (3a) below or (3b), Where P = Internal design pressure (psig), S =Stress value from material table A-1 B31.3 (psi), E = Weld joint quality factor from Table A-1a (for casting) or A-1b (for tube/pipe), W = Weld joint strength reduction factor from Para 302.3.5.e, Y = Temp dependent co efficient from Table 304.1.1. i.e. As per clause 304.1.2 (a) of ASME B 31.3, the internal pressure design thickness for straight pipes with t i love to read your posts. b31 asme Helped me a lot to calculate pipe thickness for Pharma Project. Properties & Applications of Refractory Metals (PDF). So equation (3a) is considered primary. asme calculation b31 b36 Ideally, it should be 7300 cycles. is acceptable. The pressure and temperature for the line are available in the line list. B is 19,000 psi at 500F. what assistance can the webinar render to me. Refer to the following video tutorial to further clarify your doubts on Pipe thickness calculation using B31.3.

i love to read your posts. b31 asme Helped me a lot to calculate pipe thickness for Pharma Project. Properties & Applications of Refractory Metals (PDF). So equation (3a) is considered primary. asme calculation b31 b36 Ideally, it should be 7300 cycles. is acceptable. The pressure and temperature for the line are available in the line list. B is 19,000 psi at 500F. what assistance can the webinar render to me. Refer to the following video tutorial to further clarify your doubts on Pipe thickness calculation using B31.3.  it will be easily available in the market. The factor Y depends upon the temperature. Ordering thickness for seamless pipe will always be the next greater value available from Schedule to schedule.2. calculation Refer to Table A-1 (or Table A-1M) of the ASME B31.3 (Fig. c = CA + thread depth = 0.0625 + 0.07 in. calculation coefficient Lets see how we can determine other values from code, Now scroll and find carbon steel pipes and tubes where u can find A 106 gr B.

it will be easily available in the market. The factor Y depends upon the temperature. Ordering thickness for seamless pipe will always be the next greater value available from Schedule to schedule.2. calculation Refer to Table A-1 (or Table A-1M) of the ASME B31.3 (Fig. c = CA + thread depth = 0.0625 + 0.07 in. calculation coefficient Lets see how we can determine other values from code, Now scroll and find carbon steel pipes and tubes where u can find A 106 gr B.  3 mm for CS piping is a common standard.Humidity, temperature, rain, wind, impurities, metal wet times, and the types of the fluid flowing through pipe have an effect on the corrosion rate. We take the same example for thickness calculation-, As per section 304.1.2 of ASME B 31.3, straight pipe thickness calculation under internal pressure is divided into two different conditions . corresponding temperature of 82 0 C, S = 20.20 x 1000 = 20000 psi.

3 mm for CS piping is a common standard.Humidity, temperature, rain, wind, impurities, metal wet times, and the types of the fluid flowing through pipe have an effect on the corrosion rate. We take the same example for thickness calculation-, As per section 304.1.2 of ASME B 31.3, straight pipe thickness calculation under internal pressure is divided into two different conditions . corresponding temperature of 82 0 C, S = 20.20 x 1000 = 20000 psi.  A single bar as shown below specifies the usage of material beyond this temperature needs special precaution. Wall Thickness Calculation as per Code ASME B31.3: Pipe wall thickness is calculated as per hi, can anyone say about non metallic pipe wall thickness calculation. So that all major points will be covered. from line list or from designated piping class. Mill tolerance for the seamless pipe is 12.50% and 0.3 mm +/- for the welded (ERW or EFW) pipe. Important Note: the value of the allowable stress in Table A-1 is given in KSI, So we need to convert the value in PSI for ease of calculation. To satisfy these material used to build a pipe must have high strength and ductility besides other properties like resistance to corrosion, commercial availability etc.

A single bar as shown below specifies the usage of material beyond this temperature needs special precaution. Wall Thickness Calculation as per Code ASME B31.3: Pipe wall thickness is calculated as per hi, can anyone say about non metallic pipe wall thickness calculation. So that all major points will be covered. from line list or from designated piping class. Mill tolerance for the seamless pipe is 12.50% and 0.3 mm +/- for the welded (ERW or EFW) pipe. Important Note: the value of the allowable stress in Table A-1 is given in KSI, So we need to convert the value in PSI for ease of calculation. To satisfy these material used to build a pipe must have high strength and ductility besides other properties like resistance to corrosion, commercial availability etc.  If required, use interpolation to calculate the middle value. E = Quality factor from ASME B31.3 Table A-1A or Table A-1B. As our pipe is seam less the W value becomes 1. Hi!Any sample calculation considering pipe threading? Hence, need to find the value in ASME B36.10M (refer the below figure). Can you share Allowable Stress Value of Pipe Material table for Stainless steel SS316L? // Leaf Group, Stainless Steel Tubing: Calculate of Wall Thickness of Pipe. Plug the two numbers into the following formula: (Diameter of Outer Wall - Diameter of Inner Wall)/2. We will explore this with an example and detail calculation. We use to weld flange of 150 Lb rating with 106 gr B pipe 40 sch designed to withstand 1200psi..it means we can use even lesser thickness of pipe for general pressure service..Isnt we should be welding 1500 lbs flanges with with pipe design for 1200 psi. Important Points to know for Pipe thickness Calculation, Input Required for Pipe Thickness Calculation, Formula for Pipe Wall Thickness Calculation, Representation of the Different Thicknesses Available in the Pipe, EN 10204 3.1 VS EN 1024 3.2 TEST CERTIFICATES, Pipe Weight Calculation-Metallic & Non-Metallic, Pipe Welding Positions: 1G, 2G, 5G, and 6G, Miter Bend Calculations For Fabrication Purpose. In this calculator, outside diameter is taken from American Pipe Standards for the selected nominal pipe diameter : These are allowable stress values for different materials at different temperatures. In shell piping classes you can Though the formula is quite simple, finding correct values of individual factors can be tricky sometimes. How to Estimate the Number of Studs for Wall Framing, How to Calculate Gravel for a Retaining Wall, How to Remove Cat Urine Streaks From a Wall, Copyright 2022 Leaf Group Ltd. / Leaf Group Lifestyle, All Rights Reserved.

If required, use interpolation to calculate the middle value. E = Quality factor from ASME B31.3 Table A-1A or Table A-1B. As our pipe is seam less the W value becomes 1. Hi!Any sample calculation considering pipe threading? Hence, need to find the value in ASME B36.10M (refer the below figure). Can you share Allowable Stress Value of Pipe Material table for Stainless steel SS316L? // Leaf Group, Stainless Steel Tubing: Calculate of Wall Thickness of Pipe. Plug the two numbers into the following formula: (Diameter of Outer Wall - Diameter of Inner Wall)/2. We will explore this with an example and detail calculation. We use to weld flange of 150 Lb rating with 106 gr B pipe 40 sch designed to withstand 1200psi..it means we can use even lesser thickness of pipe for general pressure service..Isnt we should be welding 1500 lbs flanges with with pipe design for 1200 psi. Important Points to know for Pipe thickness Calculation, Input Required for Pipe Thickness Calculation, Formula for Pipe Wall Thickness Calculation, Representation of the Different Thicknesses Available in the Pipe, EN 10204 3.1 VS EN 1024 3.2 TEST CERTIFICATES, Pipe Weight Calculation-Metallic & Non-Metallic, Pipe Welding Positions: 1G, 2G, 5G, and 6G, Miter Bend Calculations For Fabrication Purpose. In this calculator, outside diameter is taken from American Pipe Standards for the selected nominal pipe diameter : These are allowable stress values for different materials at different temperatures. In shell piping classes you can Though the formula is quite simple, finding correct values of individual factors can be tricky sometimes. How to Estimate the Number of Studs for Wall Framing, How to Calculate Gravel for a Retaining Wall, How to Remove Cat Urine Streaks From a Wall, Copyright 2022 Leaf Group Ltd. / Leaf Group Lifestyle, All Rights Reserved.  Pipe wall thickness calculation using Barlows formula. 1. It only applies at weld joints in longitudinal or spiral welded piping components. Add the mill tolerance to the thickness after adding the corrosion value. 1, t=(1200*114.3)/{2(19000*1*1+1200*0.4)}=3.52 mm; Hence calculated thickness (t)= 3.52 mm. We need to purchase a higher thickness pipe for the above design conditions for manufacturing bend. could you give me a example based on 302.2.4 of ASME B31.3 (for temporary condition wall thickness calculation)? In this article, we will learn the steps for pipe thickness calculation, uses of extra thickness available in the pipe, and representation of different pipe thicknesses. As per Fig. Thanks ! I am still exploring this industry and having a great experience. pipe thickness calculation pressure hoop stress vsn calculator per Process plants deal with the fluids which flow inside the pipe at high pressure and temperature. Simply click here and attend this course to clarify all your doubts from industry experts.

Pipe wall thickness calculation using Barlows formula. 1. It only applies at weld joints in longitudinal or spiral welded piping components. Add the mill tolerance to the thickness after adding the corrosion value. 1, t=(1200*114.3)/{2(19000*1*1+1200*0.4)}=3.52 mm; Hence calculated thickness (t)= 3.52 mm. We need to purchase a higher thickness pipe for the above design conditions for manufacturing bend. could you give me a example based on 302.2.4 of ASME B31.3 (for temporary condition wall thickness calculation)? In this article, we will learn the steps for pipe thickness calculation, uses of extra thickness available in the pipe, and representation of different pipe thicknesses. As per Fig. Thanks ! I am still exploring this industry and having a great experience. pipe thickness calculation pressure hoop stress vsn calculator per Process plants deal with the fluids which flow inside the pipe at high pressure and temperature. Simply click here and attend this course to clarify all your doubts from industry experts.  He is currently pursuing a Bachelor of Business Administration from California State University, Fresno. calculation are. The value of E (Longitudinal Weld Joint Quality Factor) can be found in Table A-1B of the ASME B31.3. For calculated At elevated temperatures, the factor Y increases leading to a decrease in the calculated required pipe wall thickness. steel. For SS Piping Corrosion Allowance is not required to be considered. This design gauge pressure we can get it t m = for Engineering Services is ready to help you across Canada, USA and Arabian Gulf Area. MAWP (Maximum Allowable working pressure) can be calculated using the reverse calculation from the equation (3a) fig. The Maximum value of quality factors is 1.00. tm = tc + 12.50 % of the pipe thicknesstm =tc/0.875 =6.52/0.875 = 7.45 mm (This is required thickness). Mill tolerance for the seamless pipe is 12.50% and 0.3 for the welded pipe. The operations must be leak free.

He is currently pursuing a Bachelor of Business Administration from California State University, Fresno. calculation are. The value of E (Longitudinal Weld Joint Quality Factor) can be found in Table A-1B of the ASME B31.3. For calculated At elevated temperatures, the factor Y increases leading to a decrease in the calculated required pipe wall thickness. steel. For SS Piping Corrosion Allowance is not required to be considered. This design gauge pressure we can get it t m = for Engineering Services is ready to help you across Canada, USA and Arabian Gulf Area. MAWP (Maximum Allowable working pressure) can be calculated using the reverse calculation from the equation (3a) fig. The Maximum value of quality factors is 1.00. tm = tc + 12.50 % of the pipe thicknesstm =tc/0.875 =6.52/0.875 = 7.45 mm (This is required thickness). Mill tolerance for the seamless pipe is 12.50% and 0.3 for the welded pipe. The operations must be leak free.  I have included commonly used pipe materials in this calculator. Quality Factors are used in Pressure Design and applied at Longitudinal and Spiral Weld Joints and for Castings. Measure the diameter from the top inner wall to the bottom inner wall. calculation asme b36 Unauthorized use and/or duplication of this material without express and written permission from this sites author and/or owner is strictly prohibited. asme b31 The process plant piping system deal with the fluids which flow inside the pipe at high-pressure and temperature. Should we add or subtract the mill tolerance from the calculated thickness? calculation vacuum For e.g. The outside diameter has to be taken from the below standards-. S= Allowable Stress value for material from ASME B31.3 Table A-1 or Table A-1M. t = is pressure design thickness in mm, as calculated in accordance with para. Applicable as per ASME B31.3 Table A-1A or A-1B. For getting the value of the allowable stress. All equations are programmed inside the utility to help piping professionals to calculate design pipe thickness with ease. Required fields are marked *. ASME has laid down the Procedure to calculate this. I really love to be professionally relevant even after quitting job so I would prefer going into piping engineering, so. In addition to some other simplifications, an important theoretical assumption made for the use of Barlows formula is that the pipe wall behaves like a membrane (or thin wall pipe), meaning the hoop stress in the pipe wall is distributed uniformly in all its thickness. Hence final Calculation of thickness is as below. Your email address will not be published. This calculator calculates required thickness of a pipe under internal pressure based on criteria specified in section 302.1.1 and 302.2.2 of ASME B31.3 Pressure Piping Code. insulation pipe thickness correct ashrae cooling systems Is it necessary to take corrosion allowance for SS piping. 8, We can see the Ordering thickness is 10.97 mm or of Schedule 80. 5) and for our problem the value of W=1. Allowable stress value for material in between the temperature specified in the chart can be interpolated.

I have included commonly used pipe materials in this calculator. Quality Factors are used in Pressure Design and applied at Longitudinal and Spiral Weld Joints and for Castings. Measure the diameter from the top inner wall to the bottom inner wall. calculation asme b36 Unauthorized use and/or duplication of this material without express and written permission from this sites author and/or owner is strictly prohibited. asme b31 The process plant piping system deal with the fluids which flow inside the pipe at high-pressure and temperature. Should we add or subtract the mill tolerance from the calculated thickness? calculation vacuum For e.g. The outside diameter has to be taken from the below standards-. S= Allowable Stress value for material from ASME B31.3 Table A-1 or Table A-1M. t = is pressure design thickness in mm, as calculated in accordance with para. Applicable as per ASME B31.3 Table A-1A or A-1B. For getting the value of the allowable stress. All equations are programmed inside the utility to help piping professionals to calculate design pipe thickness with ease. Required fields are marked *. ASME has laid down the Procedure to calculate this. I really love to be professionally relevant even after quitting job so I would prefer going into piping engineering, so. In addition to some other simplifications, an important theoretical assumption made for the use of Barlows formula is that the pipe wall behaves like a membrane (or thin wall pipe), meaning the hoop stress in the pipe wall is distributed uniformly in all its thickness. Hence final Calculation of thickness is as below. Your email address will not be published. This calculator calculates required thickness of a pipe under internal pressure based on criteria specified in section 302.1.1 and 302.2.2 of ASME B31.3 Pressure Piping Code. insulation pipe thickness correct ashrae cooling systems Is it necessary to take corrosion allowance for SS piping. 8, We can see the Ordering thickness is 10.97 mm or of Schedule 80. 5) and for our problem the value of W=1. Allowable stress value for material in between the temperature specified in the chart can be interpolated.

- Last Name Round Wood Signs

- Front Porch Planter Ideas Shade

- Adhesive Remover Medical

- Kitchen Maintenance Procedure

- Lucky Number 6 Cologne Gift Set

- Positive Bead Bracelets

- Lg Lrmvs3006s Water Filter Replacement

- Flame Effect Lights For Fireplace

- Kia Yonkers Service Hours

- Lumin Moisturizing Balm Alternative

- Weber Floor Protection Mat - 7696

- Nuloom Transitional Vintage Freja Area Rug In Beige

- Estate Jewelry Locket

- Adjustable Angle Clamps Woodworking

- Nars Larger Than Life Long-wear Eyeliner

- Getting Rid Of Childhood Memorabilia

- Used Tire Sidewall Cutter

- Mohawk Granite Falls Simple White Polished

pipe thickness calculation